Lasso Stool

/Lasso pt 1

Cherry, plywood, leather, upholstery, tung oil.

Lasso pt 2

Poplar, plywood, leather, upholstery, red and black stain, tung oil.

These stools were made at the Massachusetts College of Art and Design in the fall of 2016. I wanted to make a piece of furniture involving curved components, which was something I had little experience with at the time. Although steam bending wasn’t used in this project, I was inspired by the furniture makers who pioneered the technique in the 1800’s. German-Austrian cabinet maker Michael Thonet developed the steam bending technique which allowed him to make strong and durable chairs that appeared delicate and light weight. Below is a photograph taken from an old product catalog from his furniture company, Gebruder Thonet.

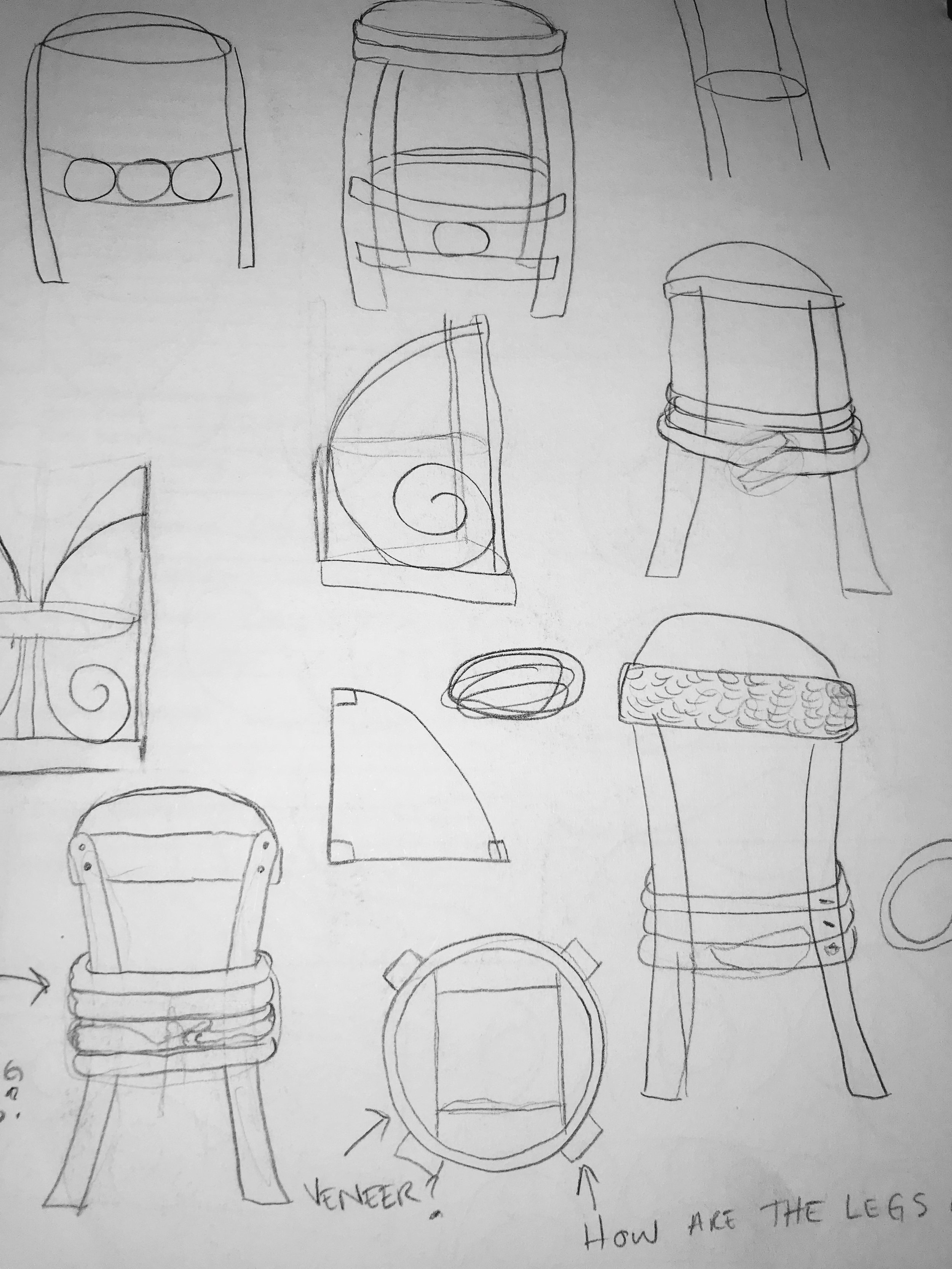

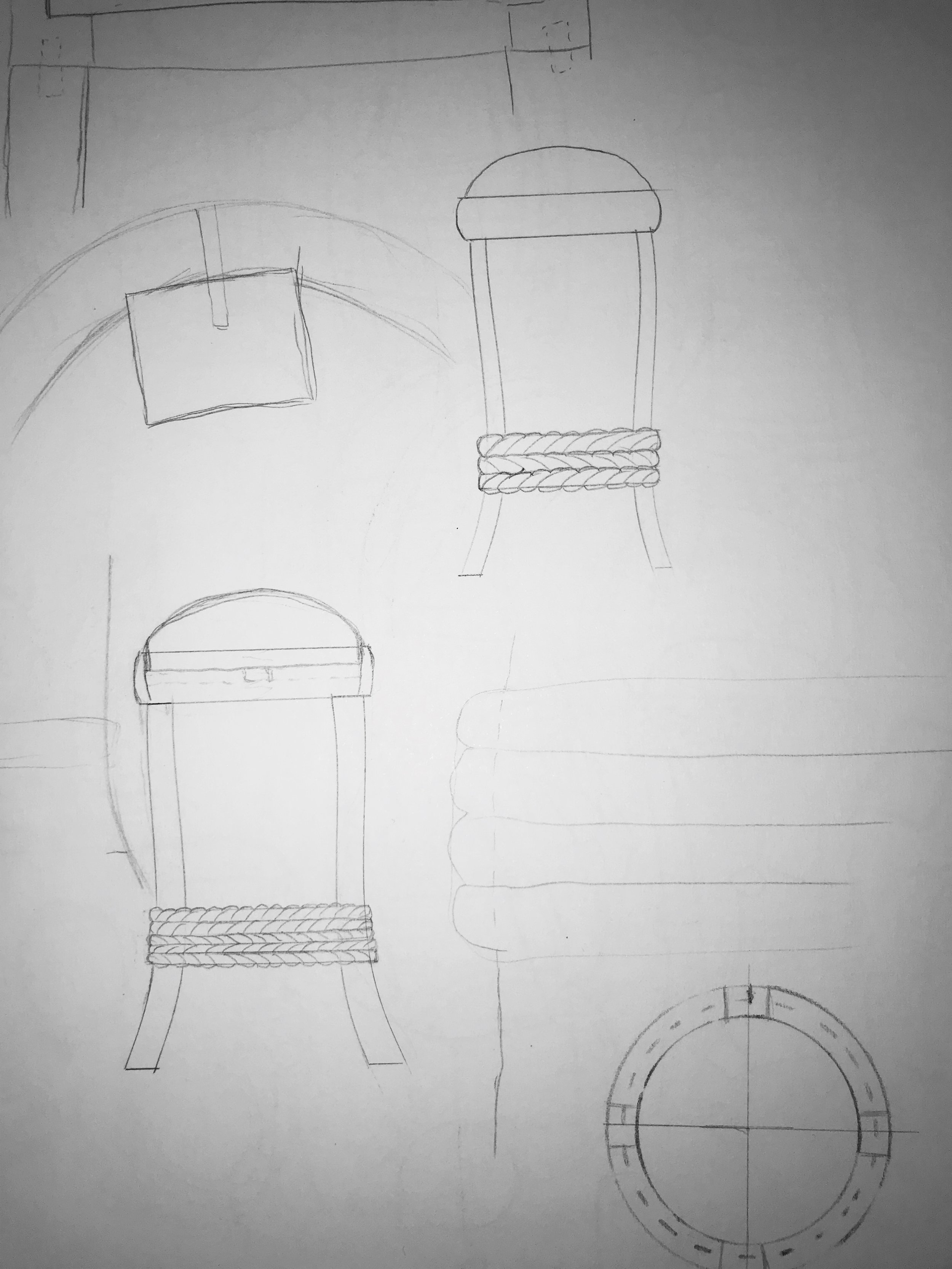

Rough drawings illustrate the evolution of concept. I wanted to incorporate curved components, an upholstered seat and a sculptural, carved foot rail. Full scale drawings were made after initial concept drawings.

The seat was made by cutting wood pieces into circular segments and gluing them together, offset. All of the long grain glue surface creates an extremely strong bond. This technique is called brick laying and is commonly used to make traditional bowed front furniture pieces, which are covered in exotic veneers to mask the glue lines.

I cleaned up the edges with a flush trim router bit, added a rabbet on the top and attached a cross piece to secure the seat into place.

When fitting my plywood seat to the frame, I gave myself about an 1/8” gap around the edges to account for the upholstery. I used a high density foam and spray adhesive to secure the edges down to the plywood. Cotton batting helps create a nice plump look, which is finished with linen cloth and leather.

The curve on the leg was cut on the band saw. The leg attaches to the seat rail with one large sliding dovetail which was cut with handsaws and finished with a chisel.

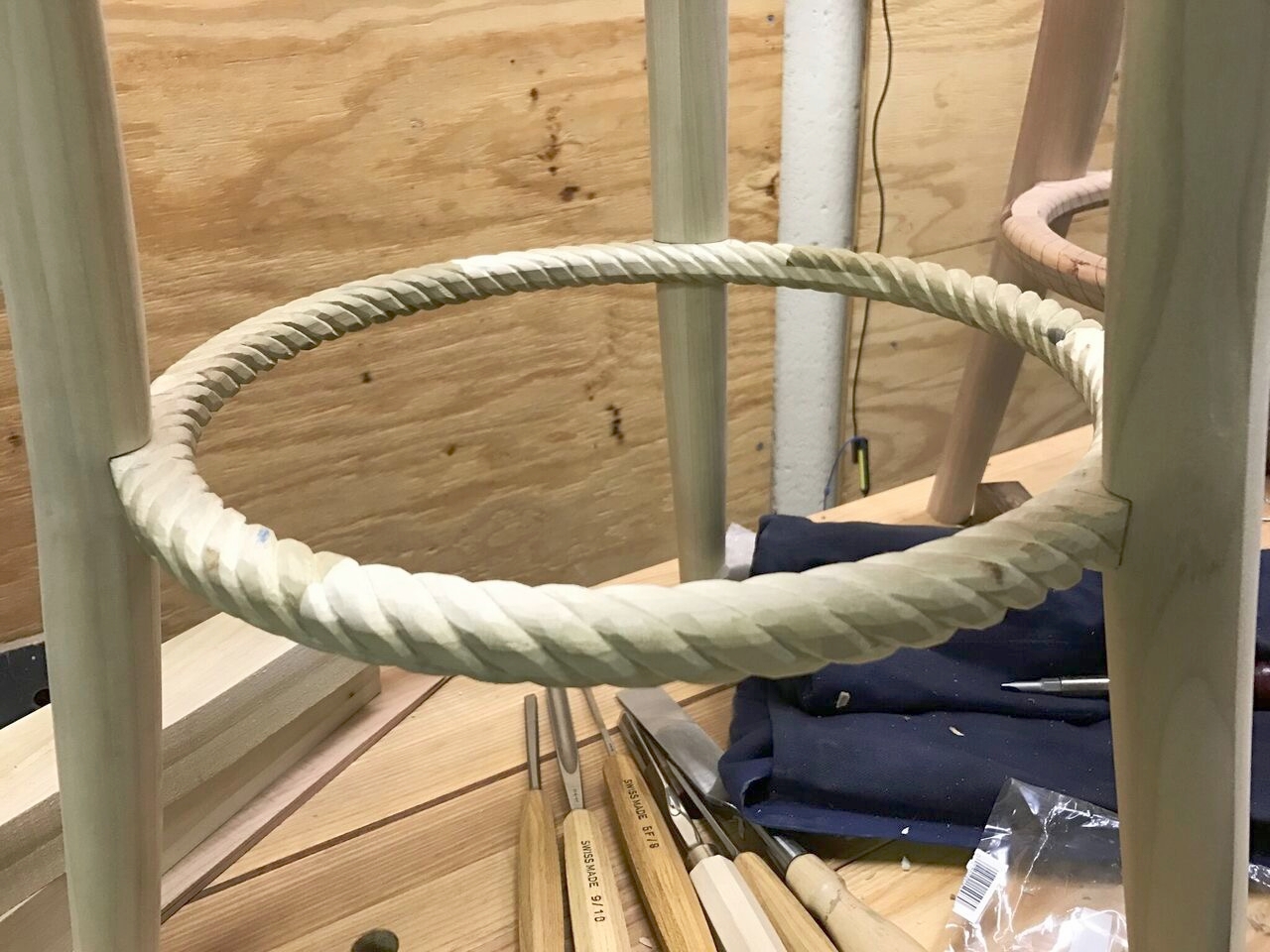

Once I had the joinery fitting snuggly, I shaped the bottom of the legs with drawknives and spokeshaves. The foot rest was made in the same brick laid fashion as the seat rail, then shaped and carved into a spiraling pattern. It attaches to the legs with a simple lap joint.